Description

Frequency Response Functions (FRF) obtained for Sandvik CoroBore® 825 XL mounted at WHN 13-15 TOS VARNSDORF CNC machine at the minimum extension of the spindle adaptor. Tool set to bore a hole with a diameter 733mm

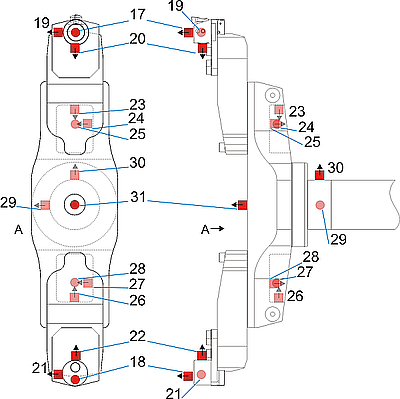

The tool was excited with modal hammer consecutively in the direction of accelerometer A18, A21, A22, A29. Responses were measured using 15 accelerometers mounted as on Fig. 1. 40 hammer impacts for each direction were performed. FRF was calculated using H3 estimator from NI LabView Sound & Vibration toolkit. Obvious disruptions in data (“peaks” resulting from the CNC control systems and drive, electromagnetic interference etc.) were removed.

Figure 1. Scheme of the Sandvik CoroBore 825 XL boring tool with marked 1-axis accelerometers positions. Black arrows indicate the positive direction of measured accelerations. Accelerometers marked with a lighter color are covered by the object.

Measurement equipment:

Modal hammer - PCB 086C03 – +-2224N

Accelerometers - DJB A/120/V – +-75g

Modal hammer connected to NI PXI 6221 DAQ card (16-bit ADC) via external IEPE conditioner.

Accelerometers connected to NI PXI 4496 IEPE DAQ card (24-bit ADC).

Sampling frequency 10 kHz

Files:

A18_FRF.txt

A21_FRF.txt

A22_FRF.txt

A29_FRF.txt

File format: Plain text, UTF-8 encoding, data in columns

Columns in each file:

1 – frequency

2…16 – FRF magnitude [(m/s^2)/N] – accelerometers from A18 to A31

17…32 – FRF phase [deg] – accelerometers from A18 to A31

33…46 – FRF coherence – accelerometers from A18 to A31

Acknowledgement:

Measurement data collected as a part of the tasks financed by the Polish National Centre for Research and Development, project TANGO1/266350/NCBR/2015, on “Application of chosen mechatronic solutions to surveillance of the large-size workpieces cutting process on multi axial machining centers”.

Experimental investigations on the WHN 13-15 TOS VARNSDORF table milling and boring CNC machine were performed thanks to cooperation with the PHS HYDROTOR Inc. in Tuchola, Poland

Dataset file

hexmd5(md5(part1)+md5(part2)+...)-{parts_count} where a single part of the file is 512 MB in size.Example script for calculation:

https://github.com/antespi/s3md5

File details

- License:

-

open in new tab

CC BY-NC-SANon-commercial - Share-alike - File embargo:

- 2021-10-01

Details

- Year of publication:

- 2021

- Verification date:

- 2021-05-19

- Dataset language:

- English

- DOI:

- DOI ID 10.34808/nhsy-hy21 open in new tab

- Funding:

- Verified by:

- Gdańsk University of Technology

Keywords

Cite as

Authors

seen 283 times