Description

In this description the results of the experiment and also simulation performed on the total assembly of the 160 EC pantograph type is given. Multibody dynamics of pantograph rising due to external torque and forces are measured for parameter validation of the pantograph model.

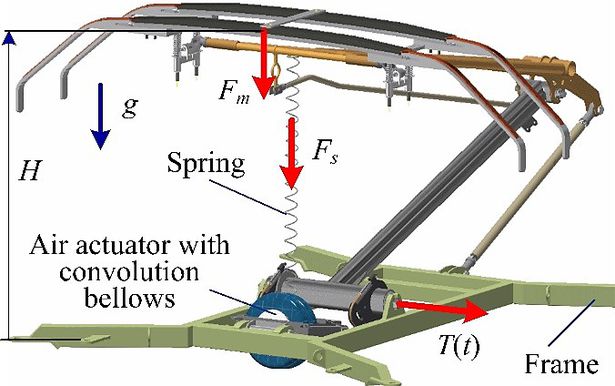

At a given initial time t = 0, the pantograph head position height was H0 = 1.04 m. Along with the force of gravity, the following forces and torques acted on its arms (Figure): torque T0 = 1110 Nm generated by the pneumatic drive to lift the pantograph arms, force Fs = 18 N coming from the external spring and used for lowering the pantograph arms, and force Fm = 78.5 N coming from an additional mass suspended from the pantograph head unit and used to lower its arms.

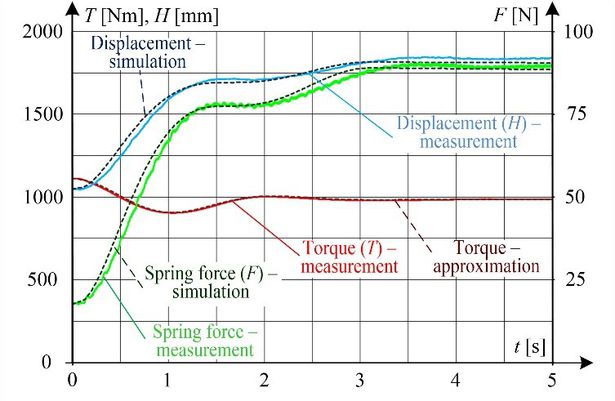

After sudden removal of force Fm (cutting off the weight of mass m = 8 kg), the transient stage began, which lasted less than 5 s. The steady-state parameter values were as follows: H = 1.84 m, T = 986 Nm, Fs = 89.5 N, Fm = 0. The quantities measured during the laboratory test were H, T, and Fs. The waveforms of these parameters from measurement and simulation are shown in Figure.

For the simulation purpose, the measured torque T(t) was approximated using an analytical function. As can be seen in Figure, this approximation correctly maps the measured torque waveform.

The structure of the pneumatic drive unit is complex. Along with the pneumatic drive, it includes the pressure and air flow control system. This unit was modelled using a simple model consisting of an equivalent spring and an equivalent damper. In the simulation process, the spring and damper parameters are additional unknown parameters. Their values were determined iteratively. The value of the elasticity coefficient kb was assumed constant, while the damping coefficient cb was expressed by a nonlinear function dependent on the speed of pneumatic drive piston rod. This model ensured good matching of simulation results to measurements. More accurate assessment of detailed parameters of individual components of the pneumatic drive model would require taking into consideration the model of its control system. This problem requires further, more advanced research.

Test of the complete pantograph: forces and torque acting on pantograph (on the left ); simulation and experimental results (on the right)

Dataset file

hexmd5(md5(part1)+md5(part2)+...)-{parts_count} where a single part of the file is 512 MB in size.Example script for calculation:

https://github.com/antespi/s3md5

File details

- License:

-

open in new tab

CC BYAttribution - Raw data:

- Data contained in dataset was not processed.

Details

- Year of publication:

- 2020

- Verification date:

- 2020-12-17

- Creation date:

- 2019

- Dataset language:

- English

- Fields of science:

-

- Automation, electronic and electrical engineering (Engineering and Technology)

- DOI:

- DOI ID 10.34808/39jh-wr68 open in new tab

- Verified by:

- Gdańsk University of Technology

Keywords

References

- publication Modal analysis of railway current collectors using Autodesk Inventor

- publication Novel analysis methods of dynamic properties for vehicle pantographs

Cite as

Authors

seen 473 times